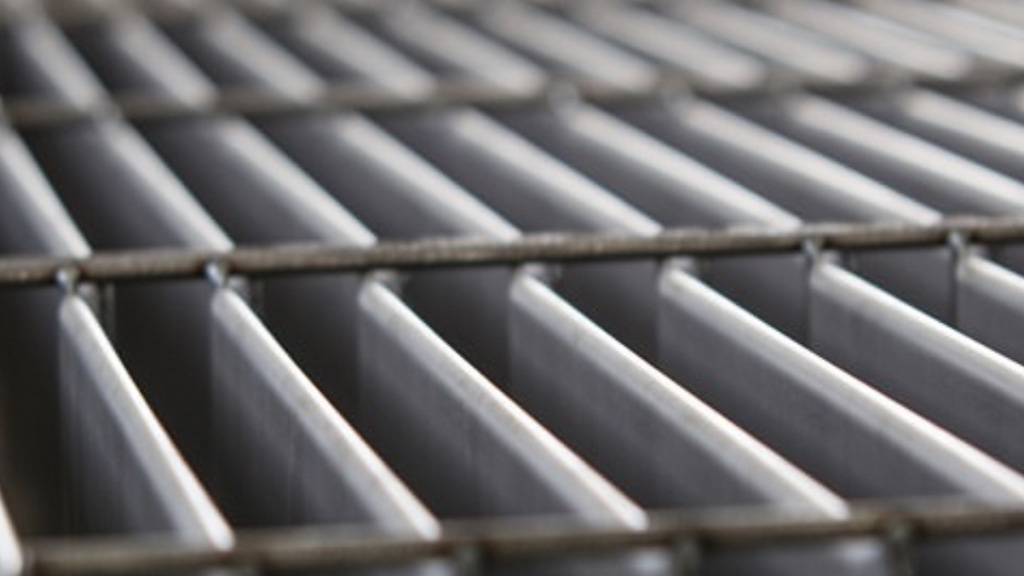

In oil-type electricity distribution and power transformers, the heat generated in the coils and core by induction damages the transformer and causes a decrease in the efficiency of the transformer. In order to eliminate this heat, transformer oil is placed in the transformer boiler to isolate the active part from the boiler and the heat generated in the active part is conventionally transferred to the atmosphere. Fin walls are cooling radiators produced as a result of folding and seam welding of monolithic roll sheet metal and used to increase the contact surface area of the transformer boiler with the atmosphere.

What is a Fin Wall Production Line?

Fin Wall Production Line

- Uncoiler

- Folding unit,

- Conveyors

- Robot welding machine,

- Spot welding machine (optional)

components. They are production lines for the production of fin walls from cold rolled coil sheet.

What are the issues affecting fin wall quality?

Manufacturing in accordance with the desired dimensions is the most important issue in fin wall production.

Diameter formation in the fin wall panel will cause the boiler to slip in the miter.

If the fin wall seam welds are not done well, there will be a leakage problem in the fin walls, and it may not be possible to eliminate this situation, and a lot of manpower will be required to eliminate it.