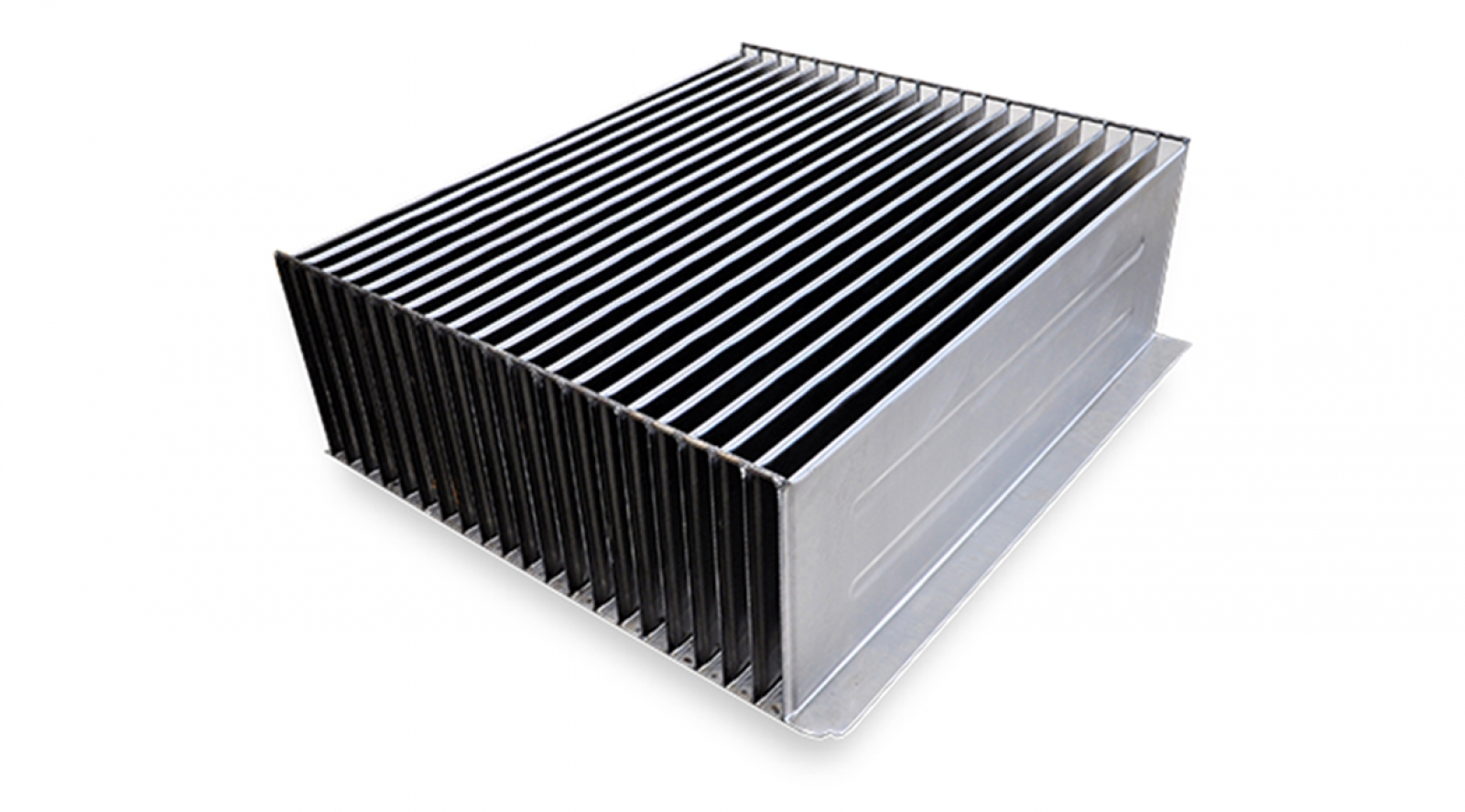

The rising temperature in the transformer core increases the kinetic energy of the cooling oil molecules. The cooling oil molecules with high kinetic energy are displaced by molecules with low kinetic energy and move towards the wall of the transformer tank. Fin walls provide cooling by increasing the contact surface of the heated oil with the atmosphere.

Fully automatic gas welding (MIG/MAG) welding machines are used to weld the fin walls used in transformer tanks. Fin walls can be manufactured with a maximum steel thickness of 1.2~1.5 mm, a width of 300~1600 mm, an internal cavity of 6-8 mm, a height of 50~400 mm and a distance between fins greater than 40 mm. Extra trans steel bars are welded on both sides of the welded panel to strengthen the fin wall.

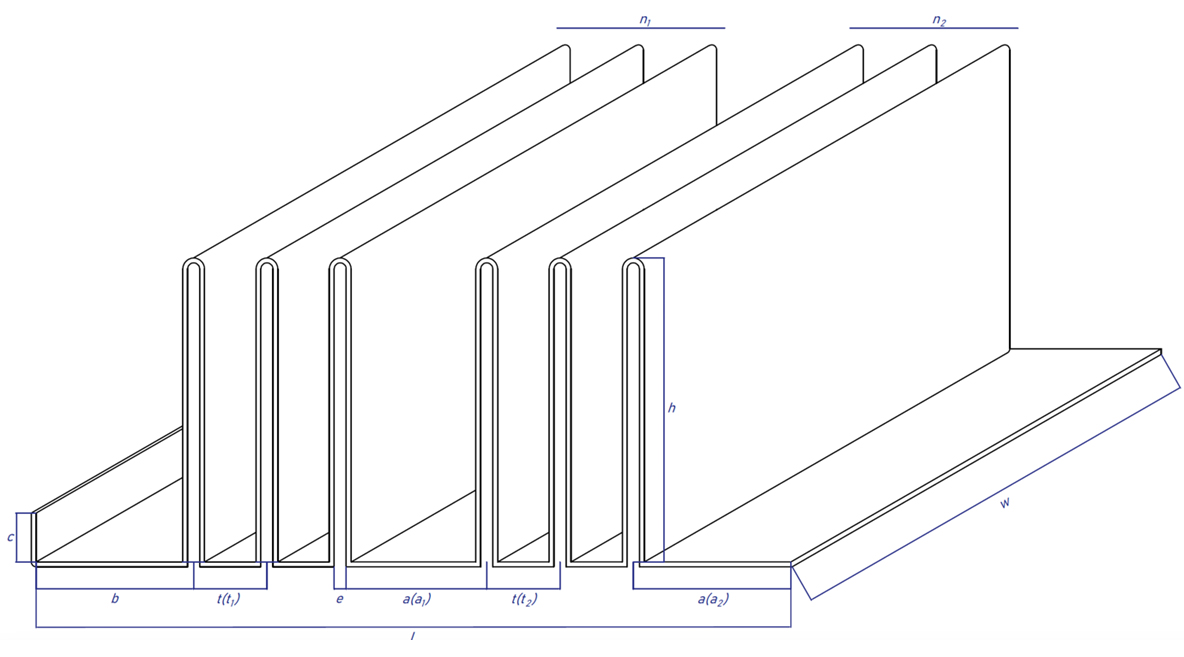

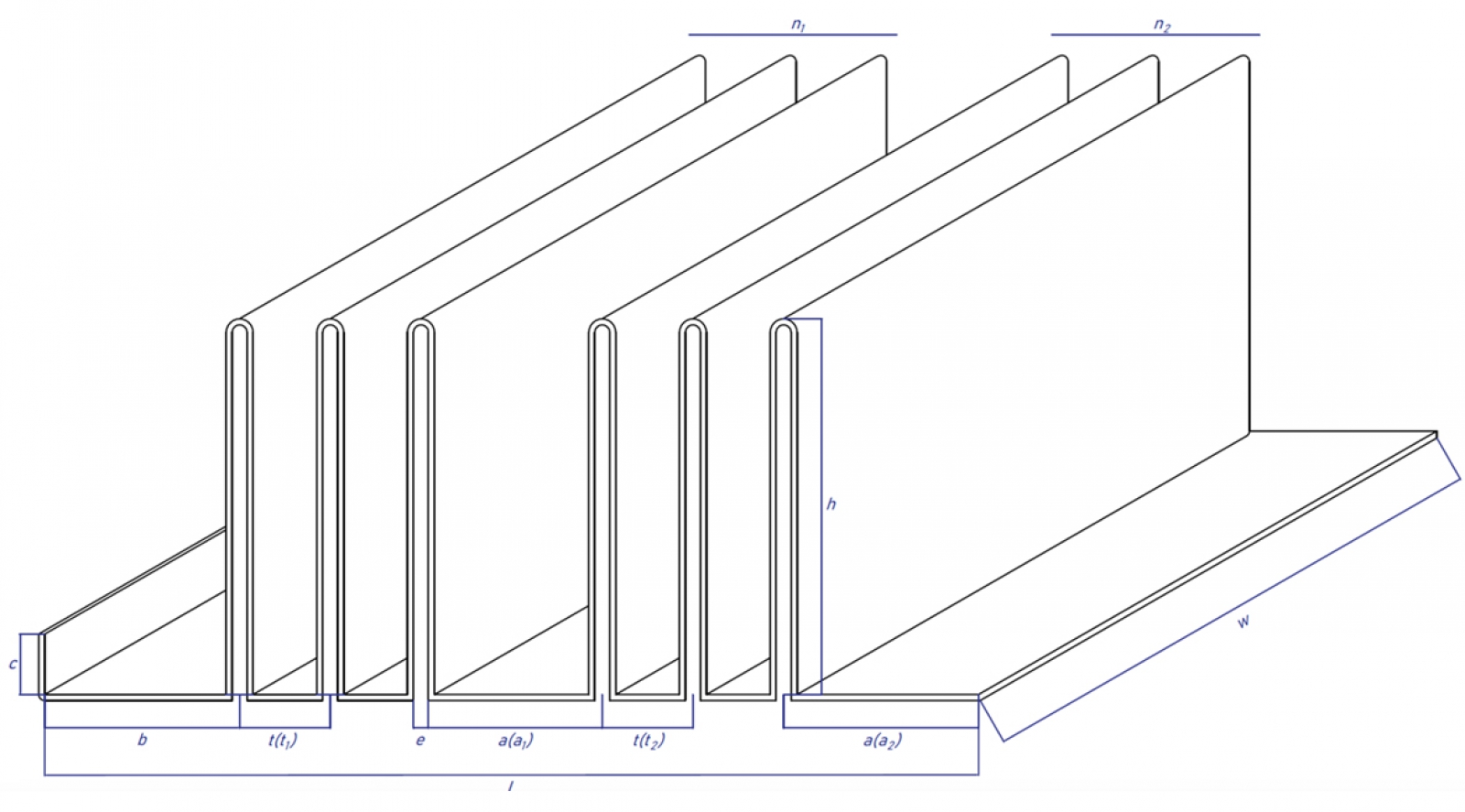

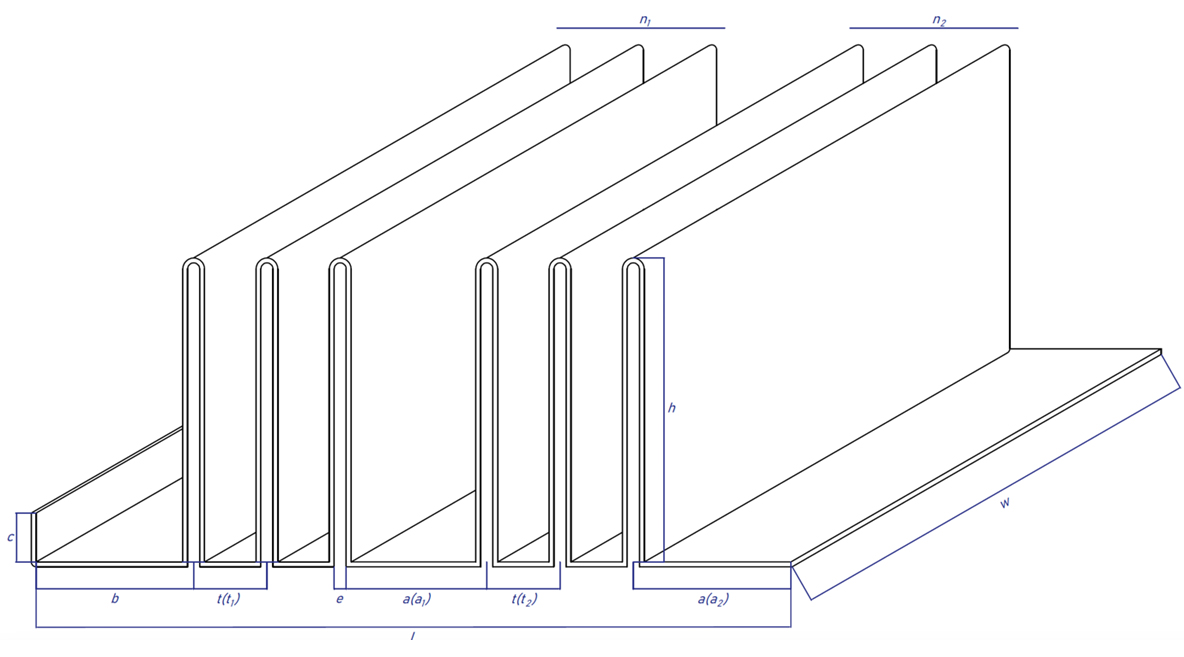

Technical specifications for corrugated walls produced by fully automatic PLC wing forming machine are shown below: