A transformer is one of the key components of energy distribution systems and is a continuously operating device. Proper and regular maintenance improves transformer performance, ensures energy efficiency and helps prevent failures.

Regular Checks:

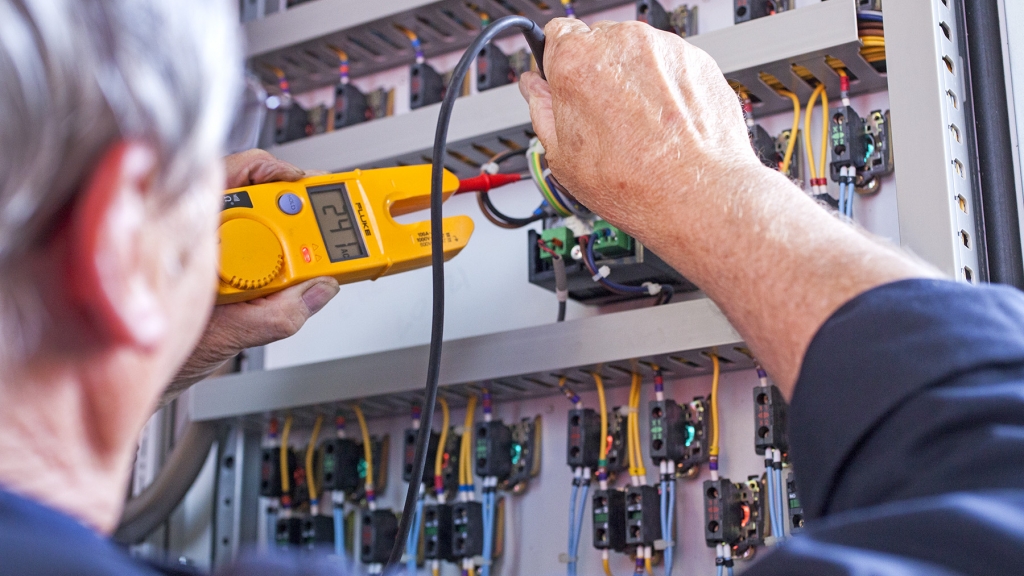

The first step of transformer maintenance is to perform regular inspections. Periodic checks carried out by specialized technicians ensure early detection of any malfunction that may occur on the transformer. During the checks, transformer cooling systems, insulation status, winding connections and protective devices are examined.

Oil Analysis:

Insulating oil used in transformers is an important component and oil analysis provides important information about transformer health. Oil analysis evaluates the electrical properties, contamination level and insulation properties of the oil. These analyses are used to detect early problems and take necessary precautions.

Cleaning and Dust Control:

Dust and dirt accumulated around the transformer can adversely affect heat dissipation and cause thermal problems on the transformer. Therefore, regular cleaning should be performed around the transformer and dust accumulation should be kept under control. Also, air filters should be cleaned or replaced regularly.

Cooling System Maintenance:

An important factor affecting transformer performance is the proper functioning of the cooling system. Cooling systems (radiators, fans, coolant) should be checked and cleaned regularly. In liquid cooled transformer systems, it should be ensured that the cooling liquid is at the proper level and has the required chemical properties.

Insulation Tests:

The integrity of the transformer insulation system is critical to its reliability and performance. Periodic insulation tests evaluate the condition of transformer windings and insulation materials. These tests provide early warning by determining how insulation properties change over time.

Control of Protections:

The transformer is equipped with various protective devices. These devices protect the transformer from situations such as overcurrent, short circuit, low oil level. Periodically, the functionality and settings of the protective devices should be checked and renewed if necessary.

Training and Documentation:

Finally, training and documentation processes related to transformer maintenance are important. Trained personnel should be familiar with transformer maintenance and troubleshooting. In addition, detailed documentation of transformer maintenance and operations should be kept. This will be useful for tracking past maintenance records and planning future maintenance.

Transformer maintenance is the basis for extending transformer life and ensuring reliability. By following these tips, you can improve transformer performance and prevent unexpected failures.